Video: How to Choose the Best Ultrasonic Cleaning Unit

Blackstone-Ney Ultrasonics covers ultrasonic cleaning beyond cavitation and implosion in this webinar.

If you already know the basics of ultrasonic cleaning and are ready for a deeper dive into its technical aspects, you will likely find this webinar titled “Ultrasonic Cleaning Beyond Cavitation and Implosion” to be helpful for gaining knowledge about how to choose the best ultrasonic cleaning unit for your application. The late John Fuchs, technology specialist, and Josh Kramlick, director of global sales, both from Blackstone-Ney Ultrasonics, a division of Cleaning Technologies Group, present on this topic and touch on:

- 19:05: Appropriate tank size and shape

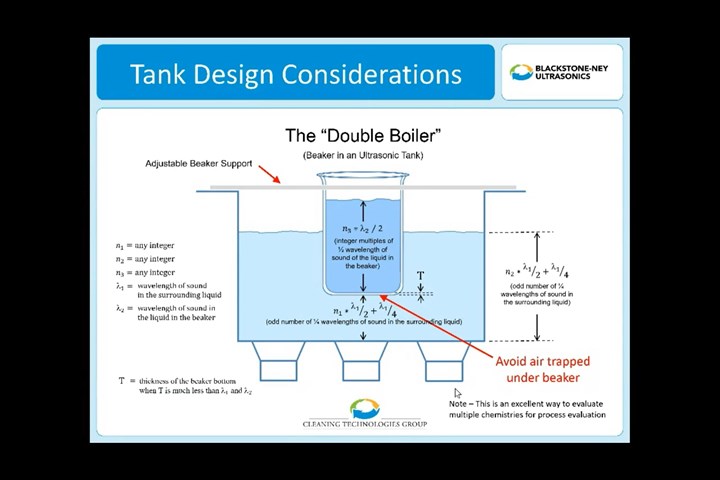

- 24:00: Advanced system configurations with a double boiler

- 27:28: Baskets and fixtures

- 35:11: Amplitude effect on cavitation

- 42:30: The effect of higher power and frequency

Thoughts about turbulation, verification of ultrasonic performance and degassing are also included in this video located on ’s YouTube channelProduction Machining.

When designing a double boiler tank, multiple wavelength separation between the inner boiler and the outer boiler tank must be considered to ensure good energy transmission for cleaning. Photo credit: Blackstone-Ney Ultrasonics.

Related Content

-

Micro-Drilling: 9 Questions to Answer Before Beginning

Applications for micromachining continue to grow. Successful machining with small tools calls for a different set of process skills on the shop floor.

-

When a CNC Turn-Mill Doesn’t Turn

A shop in Big Sky Country uses a B-axis multitasking machine to produce complex, prismatic medical parts that require no turning complete from barstock.

-

Machining More Than Metal

Plastics for medical and industrial applications present different challenges than metals as I’ve reported on over the years.